VALVES AND VALVE TRAIN

In the previous blog we have learnt very less about the valve and valve train. So let us learn more about this topic.

PURPOSE OF VALVES

Each cylinder has two valves intake valve and exhaust valve. The intake valve opens just before the intake stroke begins. This allows the air-fuel mixture to enter the cylinder( in case of diesel engine it is just air). The exhaust valve opens just before the exhaust stroke begins so that the burned gases can escape from the cylinder.

The valve are operated by the valve trains. There are two basic types of valve train

overhead camshaft with bucket tappets or rocker arms, and camshaft in block with pushrod.

Valves are arranged in many ways some of them are explained

- L-head engine

- Overhead-valve engine

- Overhead-camshaft engines

- Multivalve engine

1. L-HEAD ENGINE

It is also known as flat head engine since the head is flat. Both the valves remain at the same side of the cylinder. It was used earlier in automotive engines, but now it is used only in small engines for lawn mowers and similar equipment. It has two major drawbacks. First, it cannot be designed to have a high compression ratio. The higher the compression ratio more power the engine produces. Second, the L-head had excessive exhaust emission. The exhaust gas contains too much unburned and partly burned fuel. The reason is that the combustion chamber surfaces are large and relatively cool. This prevents complete combustion

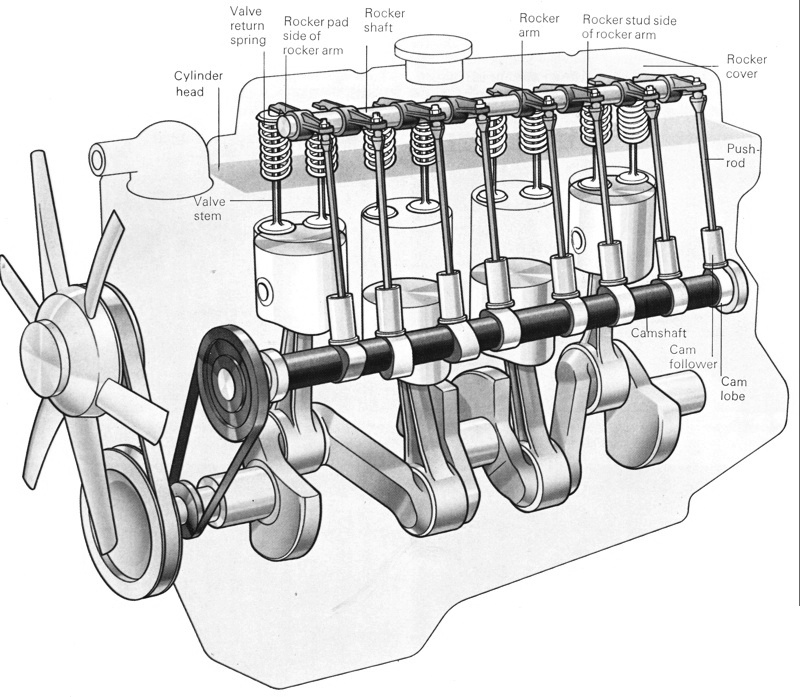

2.OVERHEAD-VALVE ENGINE

|

| In-line overhead engines |

In an overhead-valve or pushrod engine, the camshaft is in the cylinder block and the valves in the cylinder head. overhead valve engines have a higher compression ratio than L-head engine. since the clearance volume is smaller. When the air-fuel mixture is compressed into a smaller space, the compression ratio is higher. This means more engine torque and power.

some overhead engines have valve reliefs cut into the piston head as shown in the diagram. The valve reliefs provide spaces into which the valves can open without striking the piston.

When the cam lobe comes up under the valve lifter, the lobe pushes the lifter up. This pushes the pushrod up. Pushrod movement causes the rocker arm to rock on its pivot. As one end of the rocker arm moves up, the other end moves down. The valve spring is compressed as the rocker arm moves pushes the valve stem down. This forces the valve off its seat to open the valve. This is how a overhead valve engine works.

3.OVERHEAD-CAMSHAFT ENGINE

In some engines the camshaft is in the cylinder head. This kind of engine is known as overhead camshaft engine. The advantage of the overhead engine is that it reduces the inertia due to pushrod and rocker arms. The rocker arms and pushrods resist changes in speed and direction. They resist motion and change in direction until sufficient force is applied to them. As a result, the rocker arm and especially the pushrod bend or flex slightly before they open the valve. So we have to replace the pushrod often. Also flexing increases as the the speed increases, and with the length of the pushrod. This causes increasing lag in valve action and thus limits the top speed. So this is also one of the factors which decide the top speed.

As shown in the figure the camshaft is at he cylinder head. The cam lobe pushes the bucket tappet which will push the valve inside, hence the valve opens as the cam lobe moves away from the bucket tappet the valve spring moves the bucket tappet back to its original position.this closes the valve. We can use one camshaft or two camshaft as per the will. In many engines we have one camshaft for intake valves and one for exhaust vlave.

The figure also shows the chain tensioners. The reason for using chain tensioner is that, the use of the chain for long time makes it loose and hence he timing of the camshaft and other things are disturbed which is very dangeous. The chain tensioner or the timing belt continually applies a slight force to the outside surface of the chain or belt. This takes up the slack.

4.MULTIVALVE ENGINES

Engines with more than two valve in a cylinder is known as multivalve engines. The additional valve allows more air fuel mixture to enter and the exhaust gas to escape more easily. This improves the volumetric efficiency of the engine. Also the valve head diameter reduces and the valve weight is also less. This reduces the affect of inertia and reduces the valve spring force needed to close a larger valve at high engine speed.

DRIVING THE CAMSHAFT

in a generalised way two gears can be diven by many ways such as by timing gears or by sprockets and timing chain. In the figure of overhaed camshaft engine we have camshaft driven by sprockest and timing chain. Sprockets are like gears, except that the teeth are shaped to fit into the chain links. A timing chain and the sprockets usually run more quietly than gears. It is obvious that when the timing chain and sprockets are used the driving and driven gear move in the same direction unlikely the timing gears.

|

| V-belt used for many purpose |

|

| Timing gears |

Camshaft timing is the relationship between the camshaft and the crankshaft. The camshaft is driven by the crankshaft. Anything that affects this relationship may affect engine operation. There are four stroke cycle engine. The crankshaft must turn two times to turn the camshaft once, which opens each valve once. This 1:2 geat ratio is achieved by making the camshaft gear or sprocket twice as large as the crankshaft gear or sprocket.

VALVES

Now here is some more information about the valves. The intake valve is usually larger than the exhaust valve. The reason is that when the intake valve is open, the only force moving air-fuel mixture into the cylinder is atmospheric pressure. When the exhaust valve opens on the exhaust stroke, there is still high pressure in the engine cylinder. A smaller exhaust valve provides enough space for the high-pressure exhaust gases to get out of the cylinder. Some engines have three valves per cylinder. Two valves for intake and one for exhaust.

Lead was used to be used in the gasoline to increase the compression ratio. But due to its harmful effects it was banned. this lead was used to act as a lubricant. Without lead some faces and seats wear rapidly and valve seat recession occurs. To prevent this, the valves are coated with special coatings such as stellite (a very hard metal)

some valves are chrome plated stems and a hard alloy tip welded on the stem end. This reduces wear on the two areas. other valves have a hollow stem to reduce valve weight. Lighter the valve less is the inertia and hence more the power and efficient engine.

VALVE COOLING

The intake valve runs relatively cool, since it passes only the air-fuel mixture. But the exhaust valve passes the very hot exhaust gases. The exhaust valve may become red hot in operation, with temperature of up to 871 degree C.

The valve stem is the coolest. The area between the stem and the face is the hottest. The valve stem transfers heat to the valve guide to help cool the stem. The valve face transfers heat to the valve seat each time the valve closes. This helps cool the face.

|

| Valves installed in cylinder head, showing the coolant passages and types of valve guides and seat |

The valve stem and the seat are cooled by the engine cooling system.Coolant circulates through the water jackets or coolant passages around the valve seat and the valve guide in the cylinder head. Some heads have nozzles that force coolant around the valve seats. Others use deflectors in the water jackets to improve coolant circulation around the seats.

To help cool exhaust valves, some have hollow stems partly filled with the metal sodium. Sodium melts at 208 degree F. When the engine is running, the sodium is a liquid. Valve movement throws the sodium up and down in the stem. This circulation takes heat from the valve head and carries it up to the cooler stem.

some other topics are there

nice work

ReplyDeleteThank you!

ReplyDelete