AUTOMOTIVE CLUTCHES OPERATION AND SERVICE

CLUTCH CONSTRUCTION AND OPERATION

PURPOSE OF THE CLUTCH

The automotive drive train or power train- carries power from the engine to the drive wheel. In vehicles with a manual transmission or manual transaxle(transaxle includes a final drive and a differential, this is the difference between the transmission and transaxle), the power flows through a clutch. This device couples and uncouples the manual transmission and the engine. As we all know clutch are mostly operated by driver's foot. Some clutches have power assist device to reduce driver effort.

The clutch is located between the engine flywheel and the transmission or transaxle. Movement of the foot pedal operates the clutch pedal down, the clutch disconnects or disengages from the engine flywheel. In this condition no power flows from through the transaxle or transmission. When the driver releases the clutch pedal, the clutch engages. this allows the power to flow through.

Clutch is always engaged, when we push the clutch pedal clutch is disengaged(that is the clutch plate or friction disc is no more connected or coupled with flywheel or pressure plate).

The clutch is located between the engine flywheel and the transmission or transaxle. Movement of the foot pedal operates the clutch pedal down, the clutch disconnects or disengages from the engine flywheel. In this condition no power flows from through the transaxle or transmission. When the driver releases the clutch pedal, the clutch engages. this allows the power to flow through.

Clutch is always engaged, when we push the clutch pedal clutch is disengaged(that is the clutch plate or friction disc is no more connected or coupled with flywheel or pressure plate).

FUNCTIONS OF THE CLUTCH

The clutch has four functions:

- It can be disengaged(when the clutch pedal is pressed). This allows engine cranking and permits the engine to run freely without delivering the power to transmission.

- While disengaged(clutch pedal down), it permits the driver to shift the transmission into various gears. This allows the driver to select the proper gear for the operating conditions.

- While engaging (clutch pedal moves up), the clutch slips momentarily. This provides smooth engagement and lessens the shock on gears, shafts, and other drive train parts.

- When engaged(the clutch pedal up), the clutch transmits power from the engine to the transmission. All slipping has stopped.

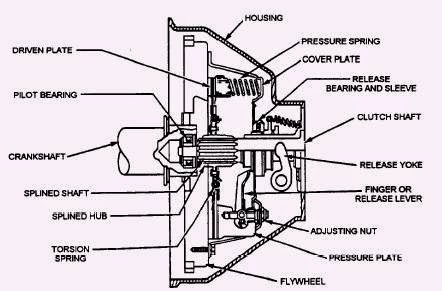

CLUTCH CONSTRUCTION

The clutch consists of three basic parts engine flywheel, a friction disk, and a pressure plate. The flywheel and pressure plate are driving members. They attach to and rotate with the engine crankshaft. The friction disc is the driven member. Friction disc is also called as driven plate or driven disc. It is splined to the clutch shaft or transmission input shaft. Flywheel and the pressure plate must turn together, but the friction disc can slide back and forth on the shaft splines.

The pressure plate, with one or more springs, attaches to the clutch cover. This pressure plate assembly bolts to the flywheel and rotates with it. While the clutch is engaged, spring force holds the friction disc against the flywheel while the clutch is engaged.

The transmission input shaft has the same center-line as the engine crankshaft. The small end of the input shaft rides in a pilot bearing or bushing in the end of the crankshaft. The transmission front bearing or transmission-input shaft bearing supports the other end of the input shaft. To know about bearings http://en.wikipedia.org/wiki/Bearing_(mechanical) this will tell you about the basics of bearing.

CLUTCH OPERATION

Disengaging the clutch(pushing the pedal down) moves the pressure plate away from the friction disc(driven plate). Releasing the clutch pedal engages the clutch. Spring force clamps the friction plate between the pressure plate and flywheel(see above fig.). Then the friction disc and the transmission input shaft turns the flywheel.

Generally when the driver depresses the clutch pedal, linkage to the clutch pedal causes it to pivot. The fork pushes against the release bearing or throw-out bearing. This forces the release bearings inwards in the pressure plate assembly. These pivot to push the pressure plate away from the friction disc. As the pressure plate moves away from the friction disc, a slight air gap opens between the friction disc and the flywheel. These air gaps disengage the clutch so no power flows through it.

Generally when the driver depresses the clutch pedal, linkage to the clutch pedal causes it to pivot. The fork pushes against the release bearing or throw-out bearing. This forces the release bearings inwards in the pressure plate assembly. These pivot to push the pressure plate away from the friction disc. As the pressure plate moves away from the friction disc, a slight air gap opens between the friction disc and the flywheel. These air gaps disengage the clutch so no power flows through it.

FRICTION DISC

It has a hub and plate, cushion springs, and dampening springs. The cushion springs attach to the plate. The friction facings attach to the cushion springs. When the clutch engages, the cushion springs compresses slightly to take up the shock of engagement.

The dampening springs or torsional springs are heavy coil springs set in a circle around the hub. The hub is driven through these springs. They help reduce the torsional vibration caused by the engine power impulses. This smoothes the power flow to the transmission.

There are grooves on both sides of friction-disc facings. These grooves prevent the facings from sticking to the flywheel face and pressure plate when the clutch disengages. The grooves break any vacuum that might form and cause the facing to stick. They also help cool the facings.

This is just the basic of the. One should also know about the clutch linkage and clutch diagnosis.

COIL SPRING CLUTCH

The pressure plate needs to be clamped. the clamping force is provided by a single diaphragm spring or by coil spring clutch. The coil spring clutch is the set in a circle between the cover and the pressure plate. Depressing the clutch pedal forces the release bearing against the release levers.Struts then carry the motion of pressure plate. It moves away from the springs against the clutch cover. This disengages the clutch.

When the clutch is engaged that is clutch pedal is released the coil springs expands and the friction disc clamps between the flywheel and the pressure plate. The coil spring must be strong enough to prevent the slippage. However, the stronger the plates, the harder the driver has to push the clutch pedal.

The solution for this is to use semi-centrifugal clutch. It has weights on the end of release levers. So when the speed increases, centrifugal force increases, causing the weights to add to the force of the springs.

DIAPHRAGM-SPRING CLUTCH

The diaphragm spring supplies the force that holds the friction disc against the flywheel. The spring has tapered fingers pointing inward from a solid ring. The spring has tapered fingers pointing inward from a solid ring. These act as release levers to take up the spring force as the clutch disengages. There are different kinds of diaphragm spring, which will not be discussed.

.jpg)

Clutch Plate Springs

ReplyDeleteI love to read this post about automotive industries! Thanks for sharing such informative blog.

ReplyDeleteKnow here about Mechanicsta's Automotive Workshop Management Software

Great breakdown of automotive drive trains! Keeping your engine running smoothly is just as important, which is why Kwik Kar Auto Dallas offers expert auto tune up service to ensure peak performance. Our Auto Repair Shop provides comprehensive Car Repair Services, Car Repair and maintenance, and professional Vehicle Repair. From routine Car Maintenance to full Automotive Repair Services, our team delivers reliable Auto Care at every step. Whether you need a trusted Car Repair Workshop or timely auto tune up service, we make sure your vehicle stays safe and efficient.

ReplyDelete